COMPANY

ABOUT ICN

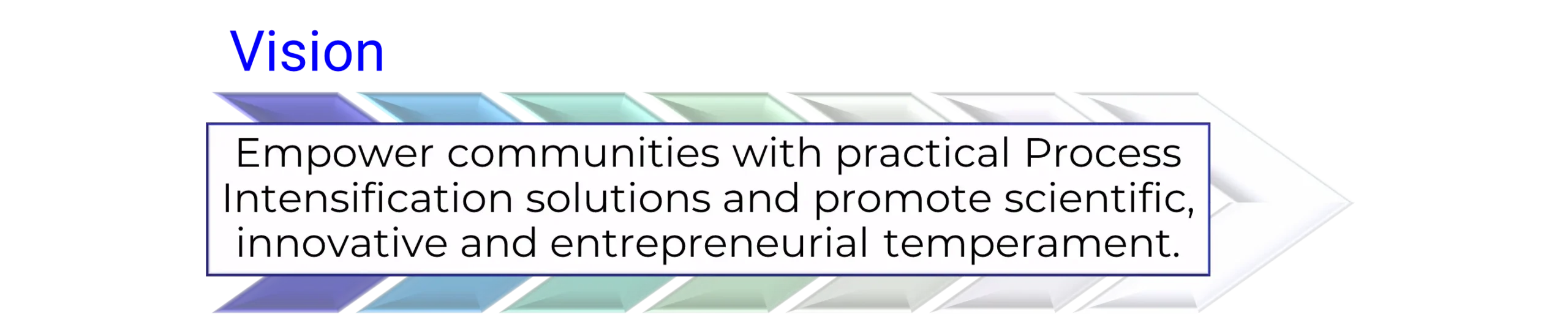

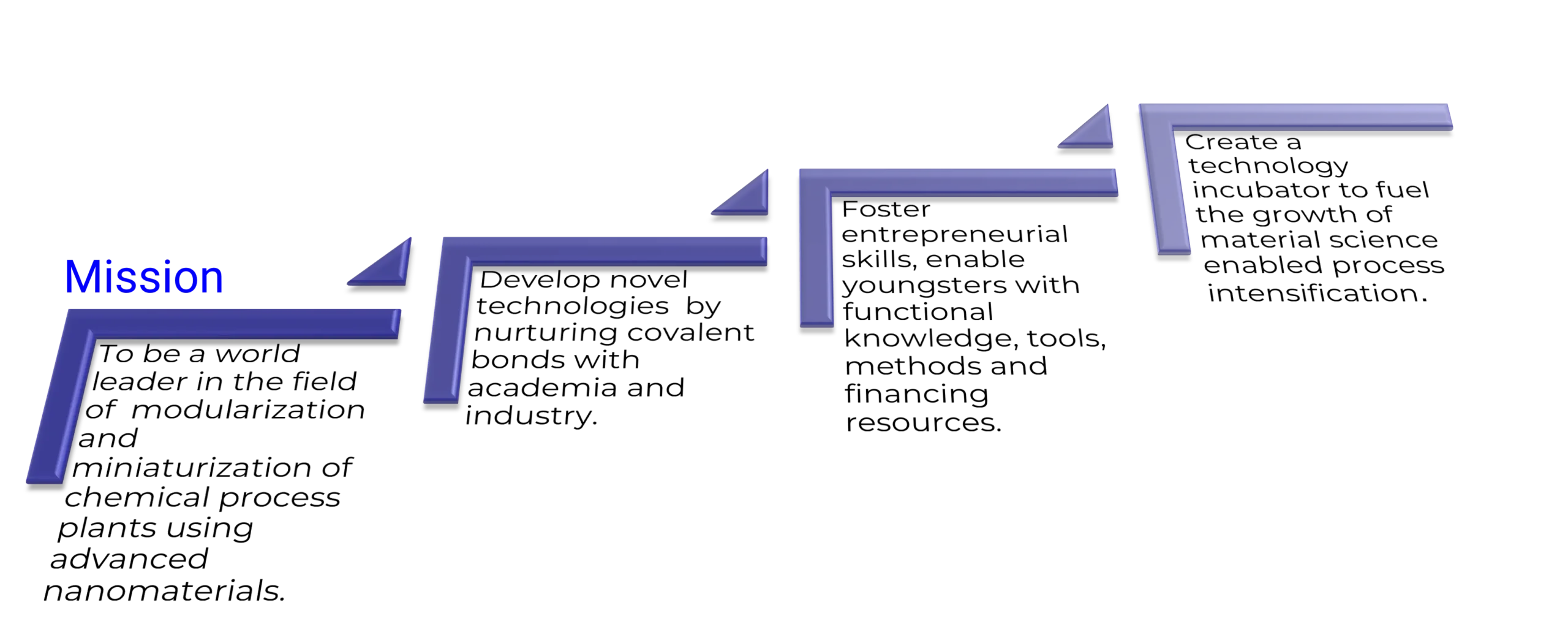

Our Vision and Mission are driven by our dedication to provide sustainable solutions to fulfil our commitment towards the society and environmental conservation and protection.

Our Beliefs

“Never doubt that a small group of thoughtful, committed citizens can change the world; indeed, it is the only thing that ever has.”

– Margaret Mead (1901 – 1978) quoted John M. Richardson, ed. Making it happen, 1982

“Nature is inexhaustibly sustainable if we care for it. It is our universal responsibility to pass a healthy earth onto our future generations”

– Sylvia Dolson

Our USPs

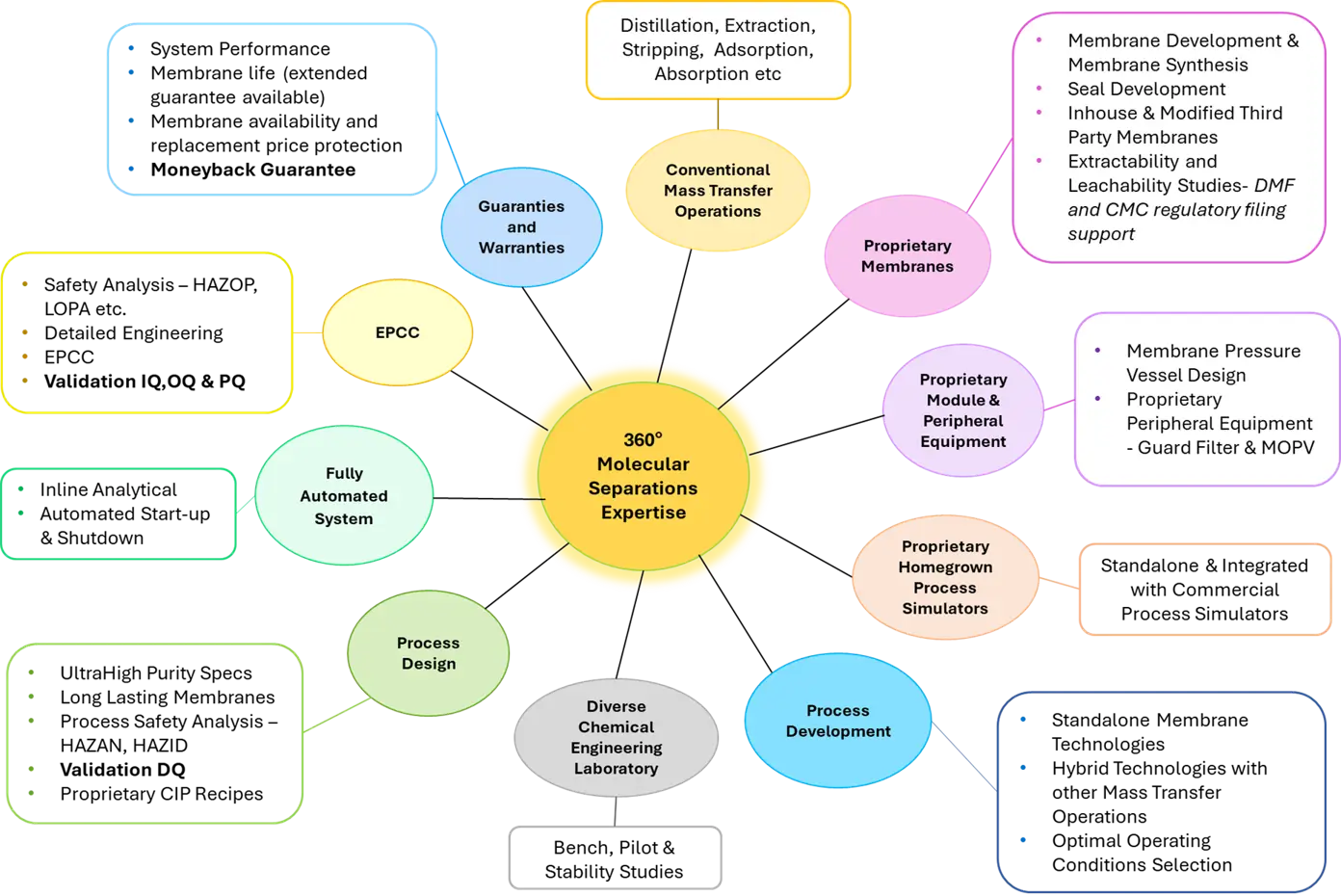

360° Molecular Separations Expertise

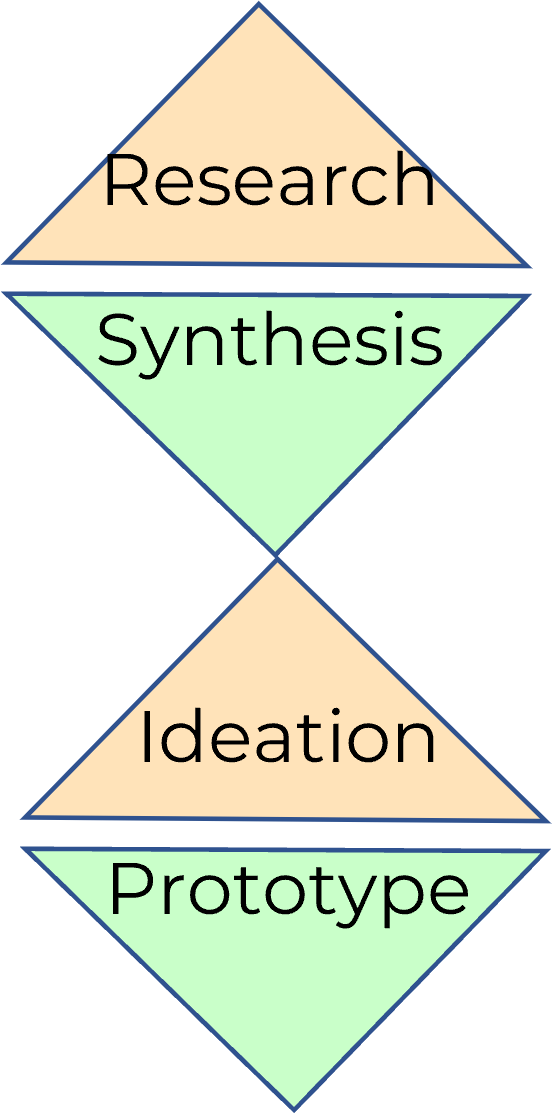

Crafted on ‘Pivotal Design Thinking’ and ‘Double Diamond Approach’, our products are designed for ease of operation for the End-user/Operator.

Our conviction that end user/operator can do no wrong – except malintent, gross negligence – is the underlying philosophy of our solutions.

MEET THE TEAM

Founder & CTO

Founded i3 Nanotec LLC based in California & Nevada, USA & I Cube Nanotec India LLP (Formerly I Cube Nanotec India Pvt. Ltd.) in 2003.

- Design Thinker and a compulsive Process Intensifier with 30 years of experience in development and commercialization of sustainable processes for a wide range of customers in Life Sciences, Specialty & Fine Chemicals, Microelectronics, Biofuels, Petrochemicals, Oil & Gas, Refining and Defense sectors.

- Active Angel Investor

- Two (2) US Patents, two (2) international patents, several research publications to his credit. Four (4) patents WIP.

- Recipient of Certificate of Accomplishment by Department of Energy, US, under the “Dawnbreaker” Commercialization Assistance Program.

- Isermann Fellow Recipient for Masters in Chemical Engineering from Rensselaer Polytechnic Institute, Troy, New York being (1993-1995).

- University Gold Medalist for B.Tech-Chemical Engineering, Osmania University, Hyderabad (1989-1993)

Formerly associated with Technip for 26 years out of 40 years in Process Industry and held position of Senior Vice President, Process & Technology, MKE Prasad is associated with us as an Advisor to our Leadership and R&D Team. An expert in Process Designing and Engineering, QHSE, Project Planning and Management possesses. He has Chemical Engineering degree from Osmania University. He also holds a diploma in Management Studies from Jamnalal Bajaj Institute of Management Studies.

Has more than 34 years of experience of working in both Academia & Biopharmaceutical Industry. Held position of Vice President, Research & Development at NATCO Pharma. An expert in manufacturing of complex generics like peptides, polypeptides, oligonucleotides & carbohydrates. Has 13+ patents in active pharmaceuticals ingredients & 32+ publications in peer reviewed journals. Contributed a chapter for book on peptides by the prestigious Royal Chemical Society. Member of United States Pharmacopoeia (USP) expert panel for Glatiramer acetate monograph and general chapter on peptides. Dr. Satyanarayana Kota is associated with us as an Advisor to our Leadership and R&D Team.

A Mechanical Engineer with 39 years of rich experience in refining industry in maintenance; start-ups, sales and project execution in public sector (Indian Oil) and technology sector (UOP). Out of this, he has 33 years of experience in project management related to Engineering, Procurement, Construction, Field Services etc. in refining area.

Has 40 years experience including 30 years association with Technip for and held the position of Senior Vice President. He is now an Advisor to our Leadership team. His expertise in Business Process Improvement, Organizational Development, Project Management & Cross functional Team Leadership is instrumental in designing and improvement of our business processes. He did Electrical Engineering from Punjab Engineering College, Chandigarh, in 1975.

WHAT WE DO?

Our Expertise

Rapid Concept to Commercialization offering quick payback

Why Green?

Developed, Designed and Manufactured on

Principles of Green Chemistry, Engineering & Manufacturing

Safe & Non-hazardous, Mild operating conditions, Low leachables & extractables, Physical separation without the use of chemicals, No side reactions, Minimal effluents & emissions, High Recovery, Low Utility Consumption, Optimal CAPEX

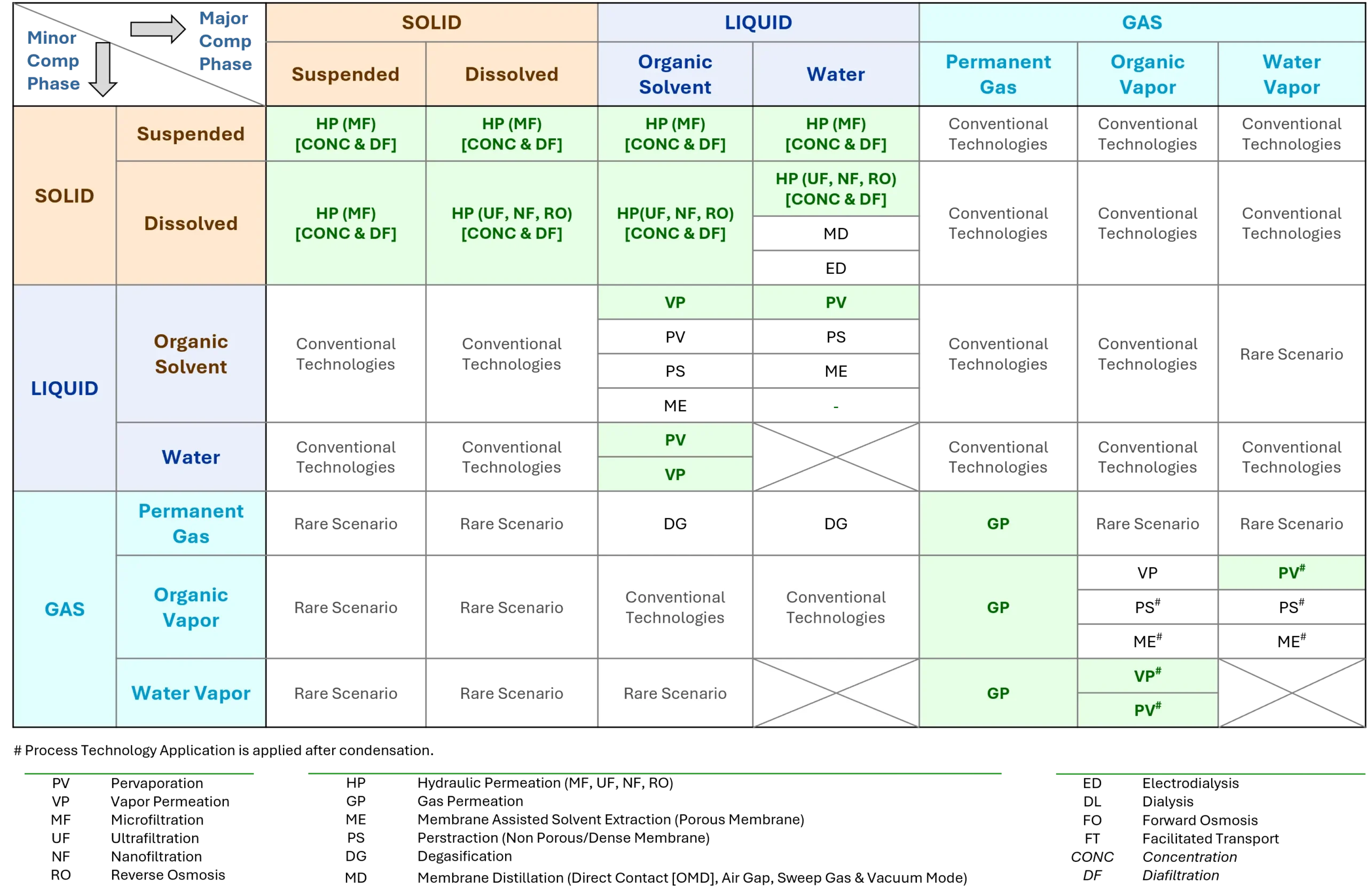

Membrane Separation Process Mode & Application Matrix

Membrane Processes are valuable separation tools that can be used for a variety of industrial applications in Life Sciences and other industries. But membranes processes do not necessarily replace conventional processes.

With our expertise in molecular separations, an overview of different process modes for membrane separations and a summary of their applications are outlined below.

This Application matrix is for high level guidance. Depending on capacity, purity requirements and variety of other factors, ideal process solution which may be a standalone or hybrid.

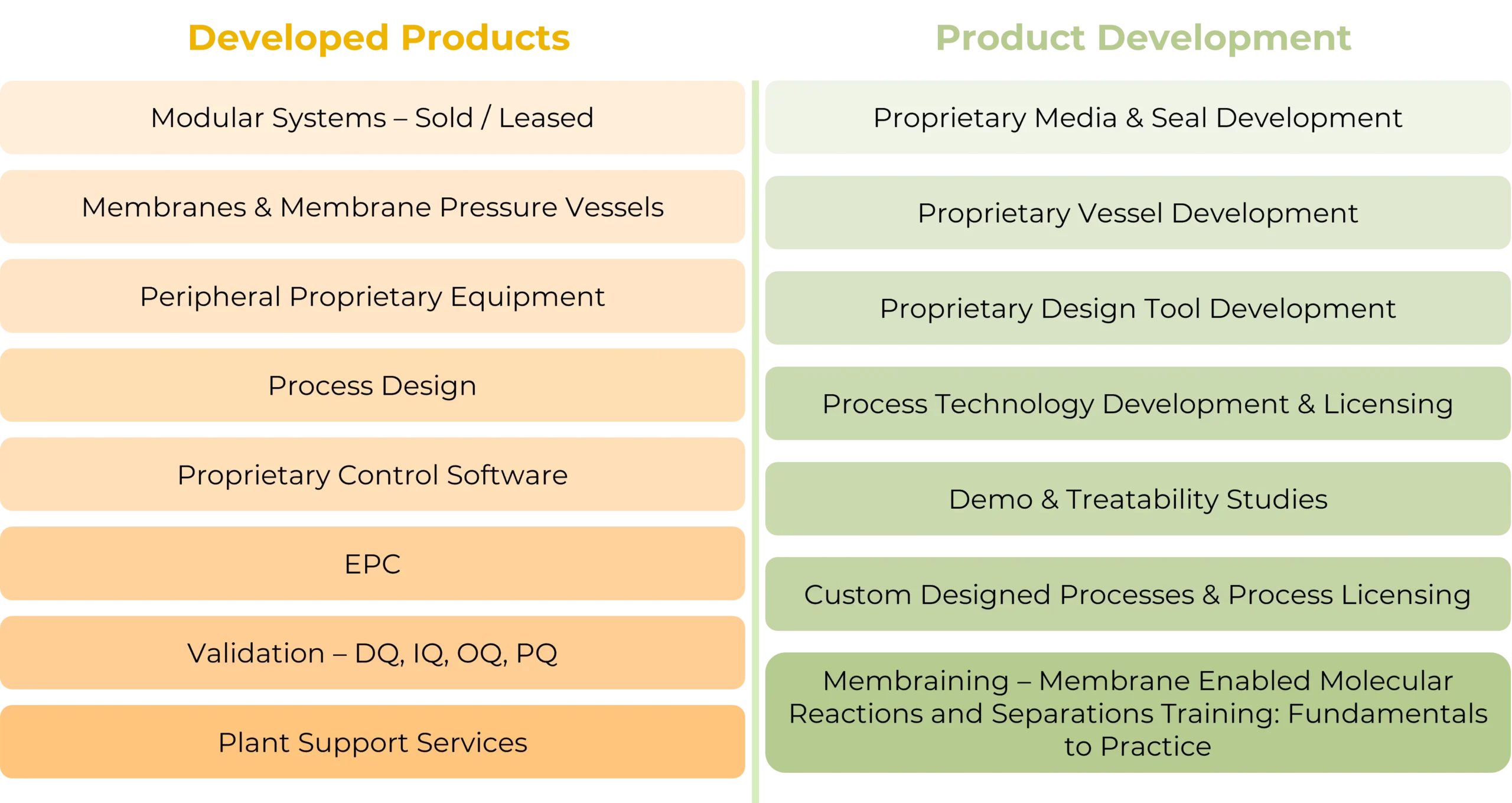

Goods & Services Offered

We sell Developed Products, but at the same time we have a strong focus on continual Product Development to develop new processes and materials. We normally do not sell product development services but there are exceptions.

Safety & Risk Management

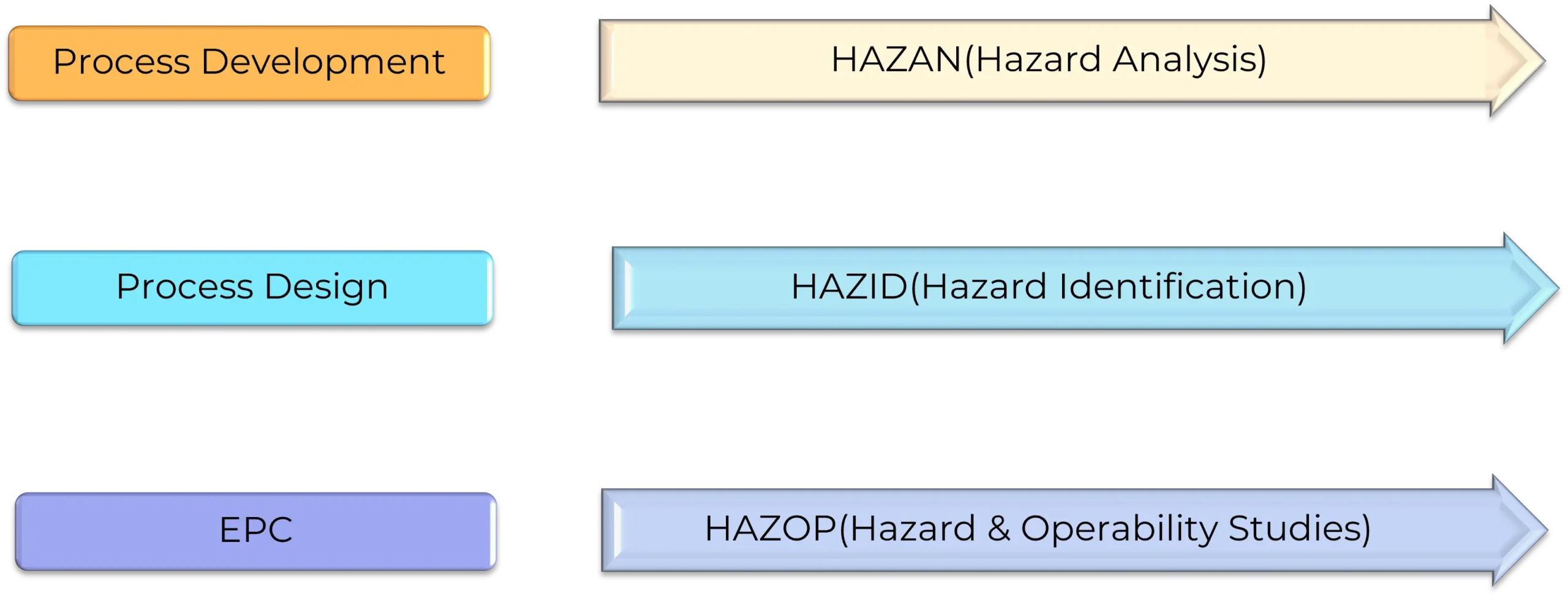

HAZAN, HAZID and HAZOP studies are conducted at appropriate stage to identify, address, reduce or eliminate hazards.

Upon completion of detailed engineering, comprehensive Risk Assessment is conducted to ensure that all risks are managed using either inbuilt process safety features and/or safety systems.

HOW WE DO?

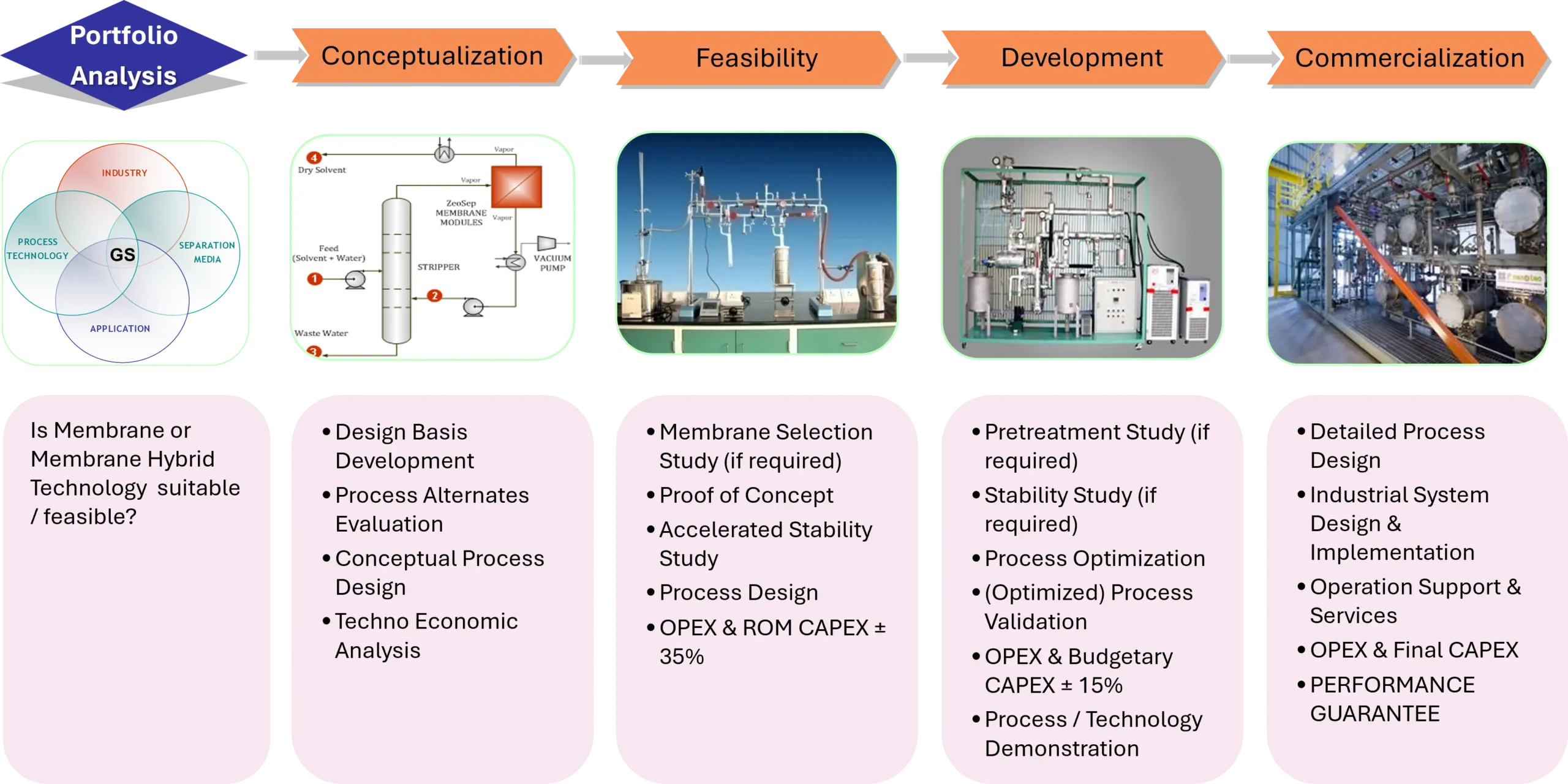

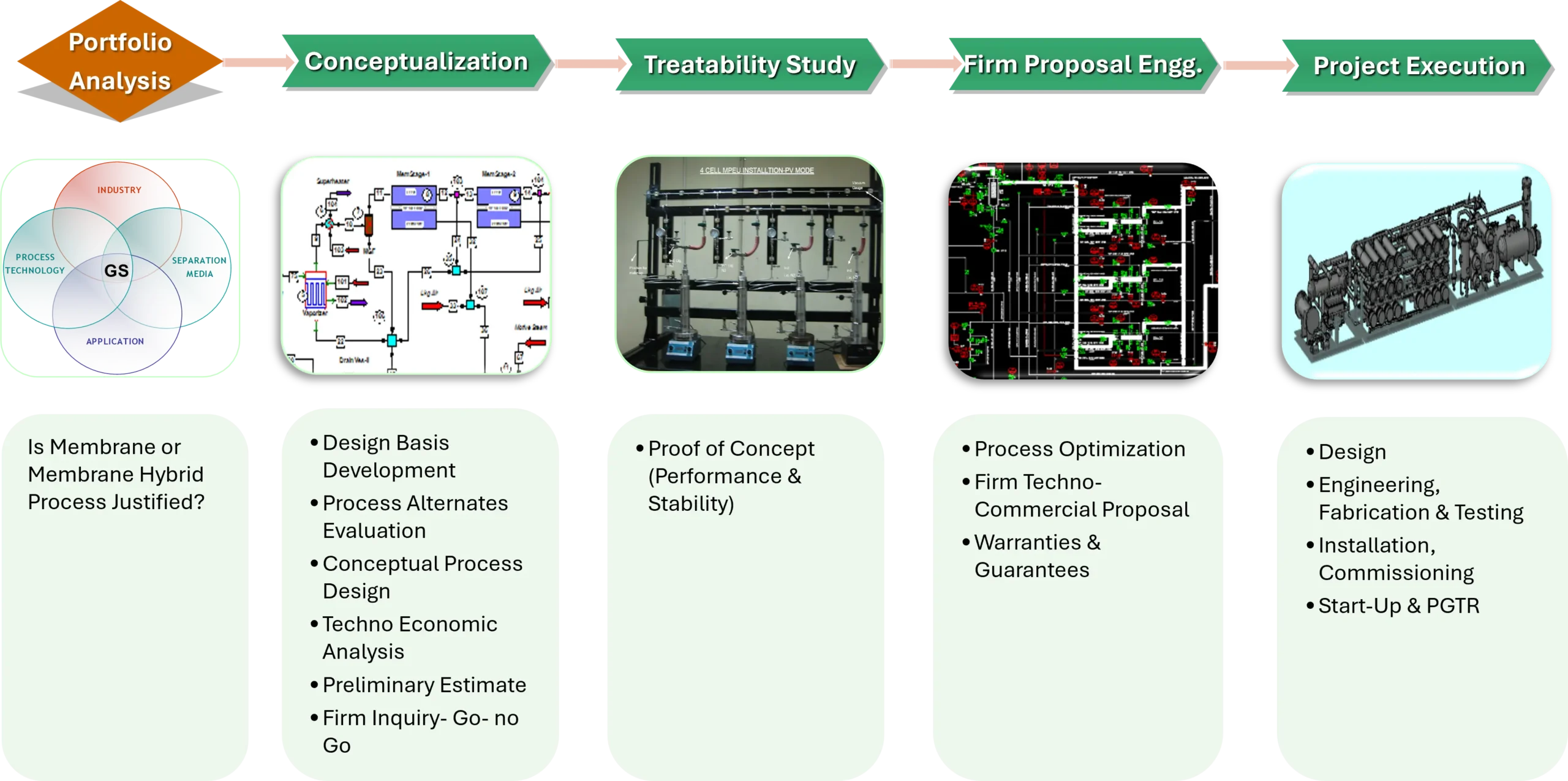

Our Approach to Industrial Application Development

Modular System Project Execution Workflow

WHERE WE DO?

Majority of our work is now being done in India. In US, we are doing manufacturing of proprietary items i.e. membranes, membrane pressure vessels, guard filter, guard filter housing, MOPV etc. In the future, we plan to move these proprietary materials manufacturing operations to India as well.

US also supports for procurement of non-proprietary items and for process design/development, engineering and manufacturing as and when required.

FACILITIES

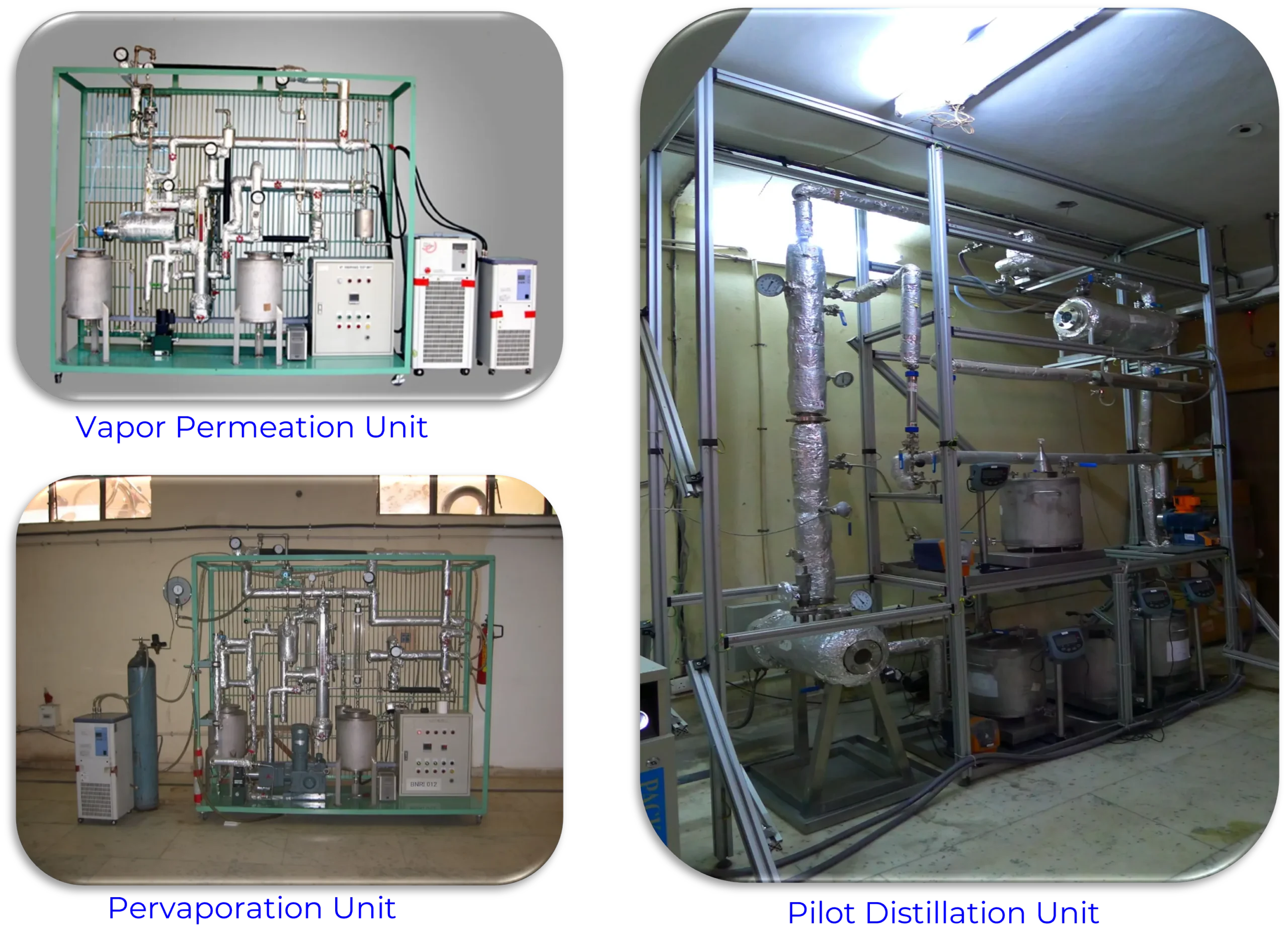

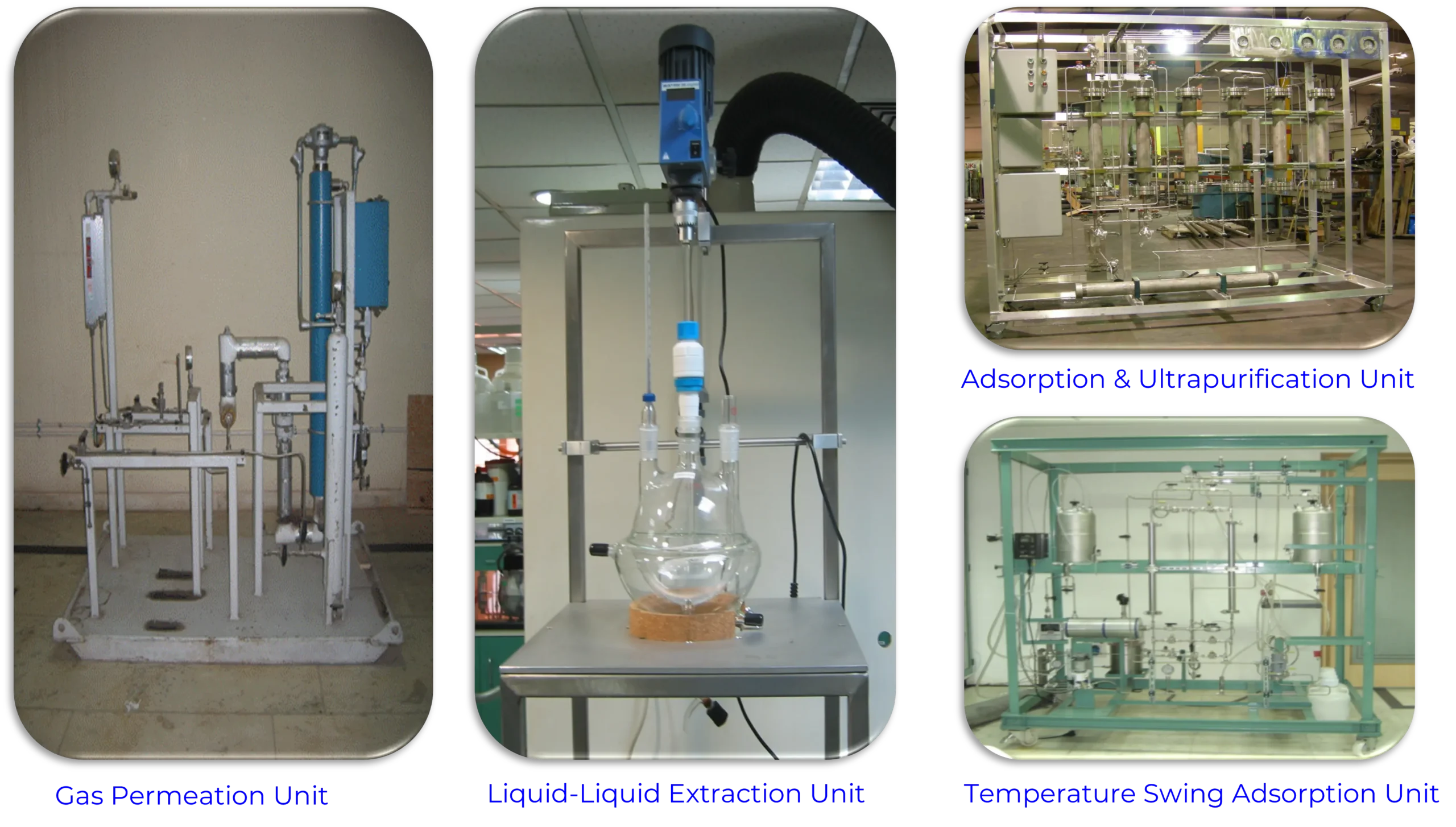

We have a fully equipped Chemical Engineering Wet Laboratory and Process Design Simulators. For Proprietary Separations, we have developed the simulation tools inhouse and they have been integrated with commercially available process simulators. We have several bench scale and pilot scale units for conducting various kinds of reactions and separations. Pictures of some of the pilot units in our Laboratory have been shown below.

Our Laboratory is also equipped with Analytical Instruments that are required to monitor the performance. Some of these Analytical Instruments are Gas Chromatograph, Karl Fischer Titrator, Refractometer, Moisture Analyzer, pH and Conductivity Meters, Density Meter etc.

For Instrumentation, Electrical, Static Equipment Design, Structural Design, Piping & 3D Modeling we all equipped with design and engineering tools. Rigorous Static Equipment & Structural Design are outsourced to our partners.

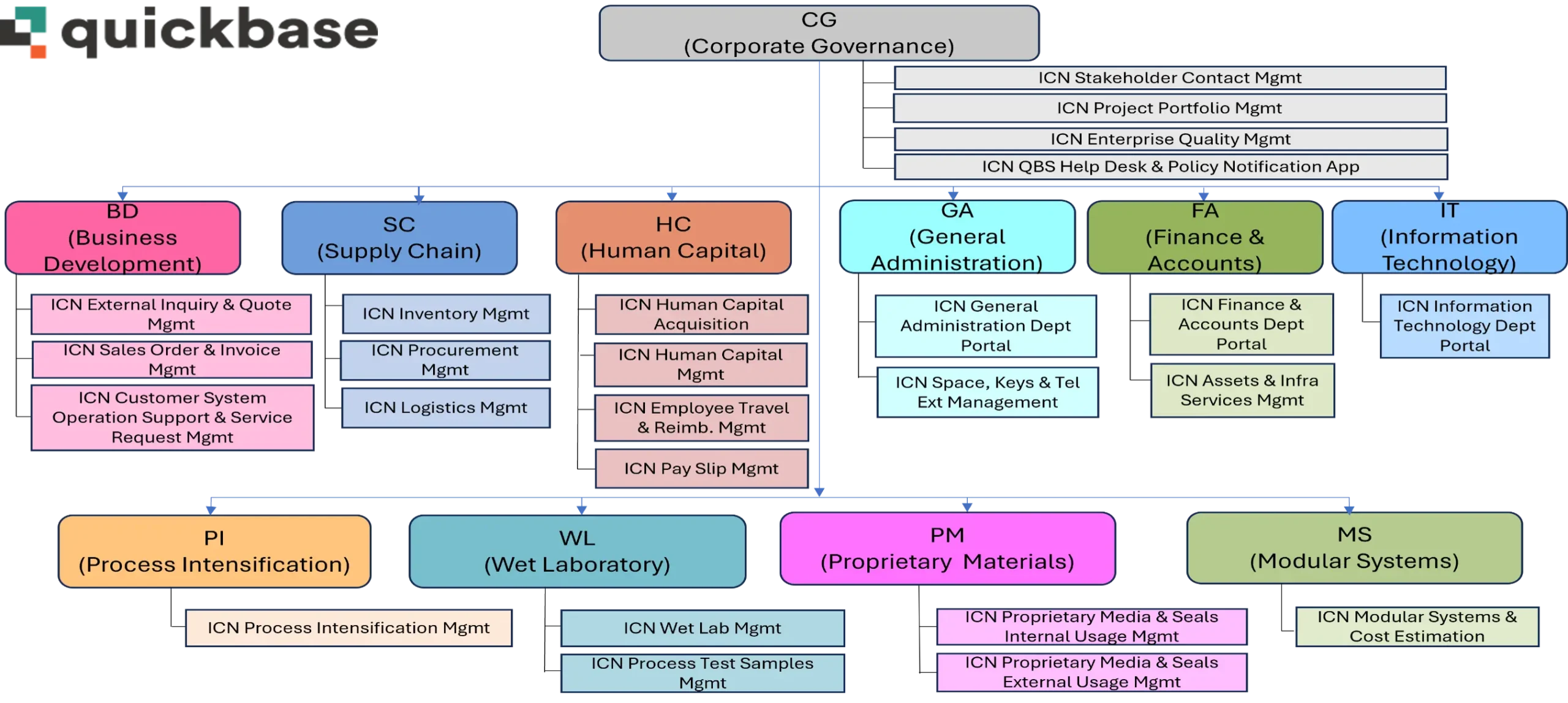

OUR FOUNDATION (ERP)

We are an incredibly Lean and Mean Team. In addition to our knowledge, Recipe for success is our Foundation – Our Home Grown, Agile, Low Code / No Code ERP System developed by our Scientists and Engineers on QuickBase Platform. Knowledge management function is intrinsically built into all our business process applications.

Use of Excel Sheets for Operations is a TABOO! All business operations have been developed and there is a business process application for every function. All these are integrated with each other. QuickBase platform has information security and customizable permissions access built in. Audit logs and application backup restore are also available.

Additionally, we are also working on integrating carbon accounting in our applications.