PRODUCTS

CUSTOM DESIGNED & ENGINEERED SYSTEMS

ICN has 360 degrees Molecular Separations Expertise and has the capability to develop a novel process, process design, engineering and execute a modular system project in a wide range of industrial sectors.

We focus on solving problems where we can offer a unique and extraordinary value proposition and do not involve in projects wherever conventional, run of the mill solutions may easily solve the problem. In fact, we routinely advise clients on using conventional solution and recommend pursuing our solutions after rigorous screening for fitment.

Our processes are developed & designed using and around our Pervaporation, Vapor Permeation & Hydraulic Permeation (Ultrafiltration, Nanofiltration & Reverse Osmosis) Technologies as Standalone or Hybrid- wherein they are often integrated with conventional mass transfer operations such as distillation, extraction, stripping, absorption, adsorption, ion-exchange and other membrane technologies, for example Gas Permeation.

Custom developed and designed processes meet all process objectives – purity, recovery, capacity with minimal OPEX and optimal CAPEX, while minimizing effluents.

Custom engineered systems are designed to meet all mechanical, structural, electrical, instrumentation & system safety requirements – layout/footprint constraints, specific codal requirements, electrical area classification and control system requirements. Depending on size and scale, they are available in variety of form factors – bench top, floor mounted with wheels, foundation mounted modular skids. They may be open frame or cabinet enclosed. For extremely large capacities, stick built construction is also an option.

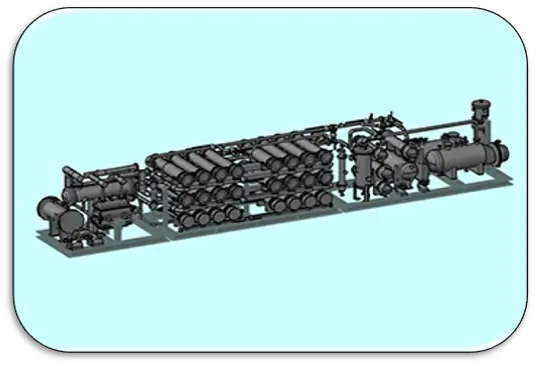

A 3D model for a modular system has been shown below.

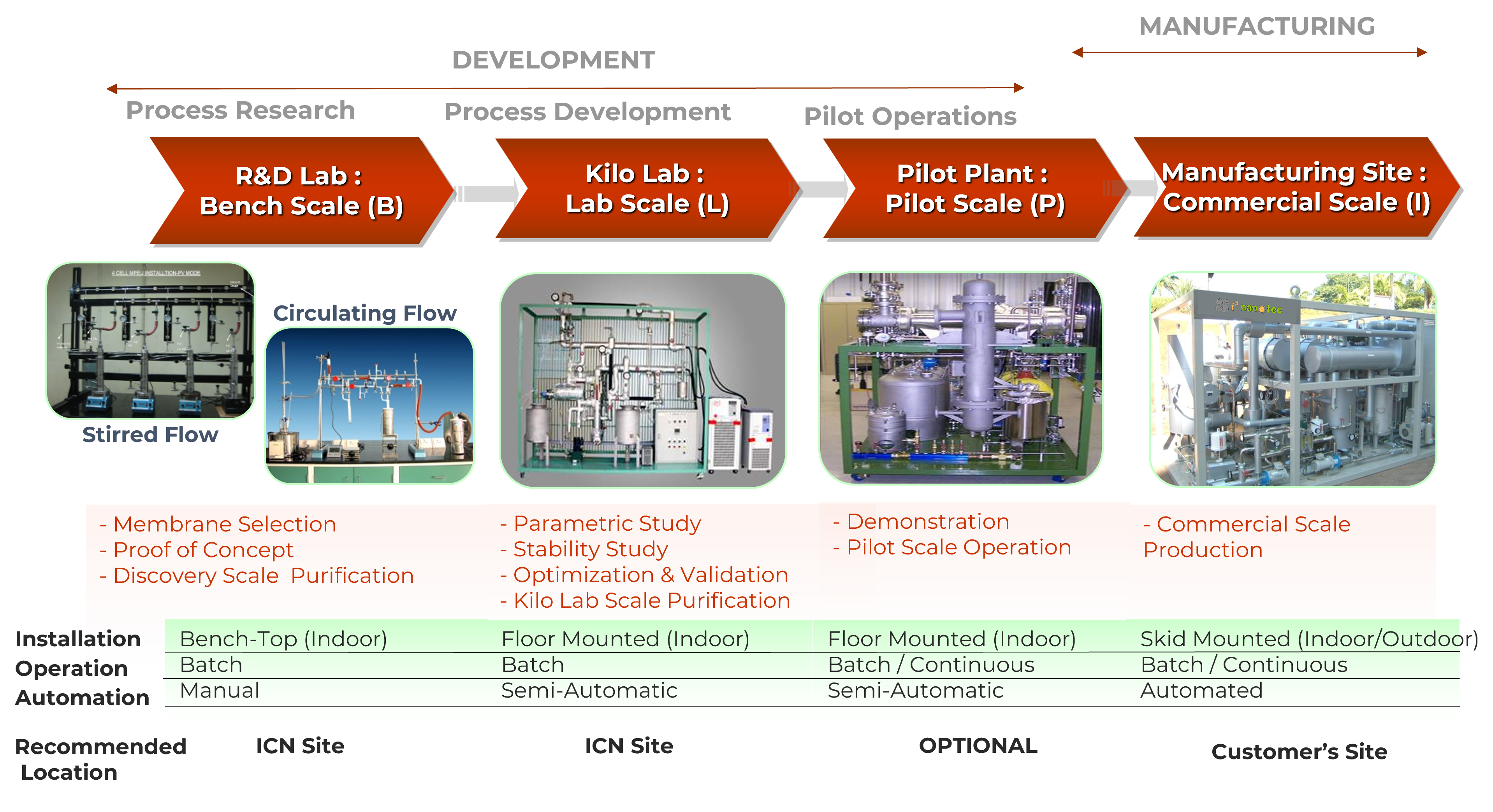

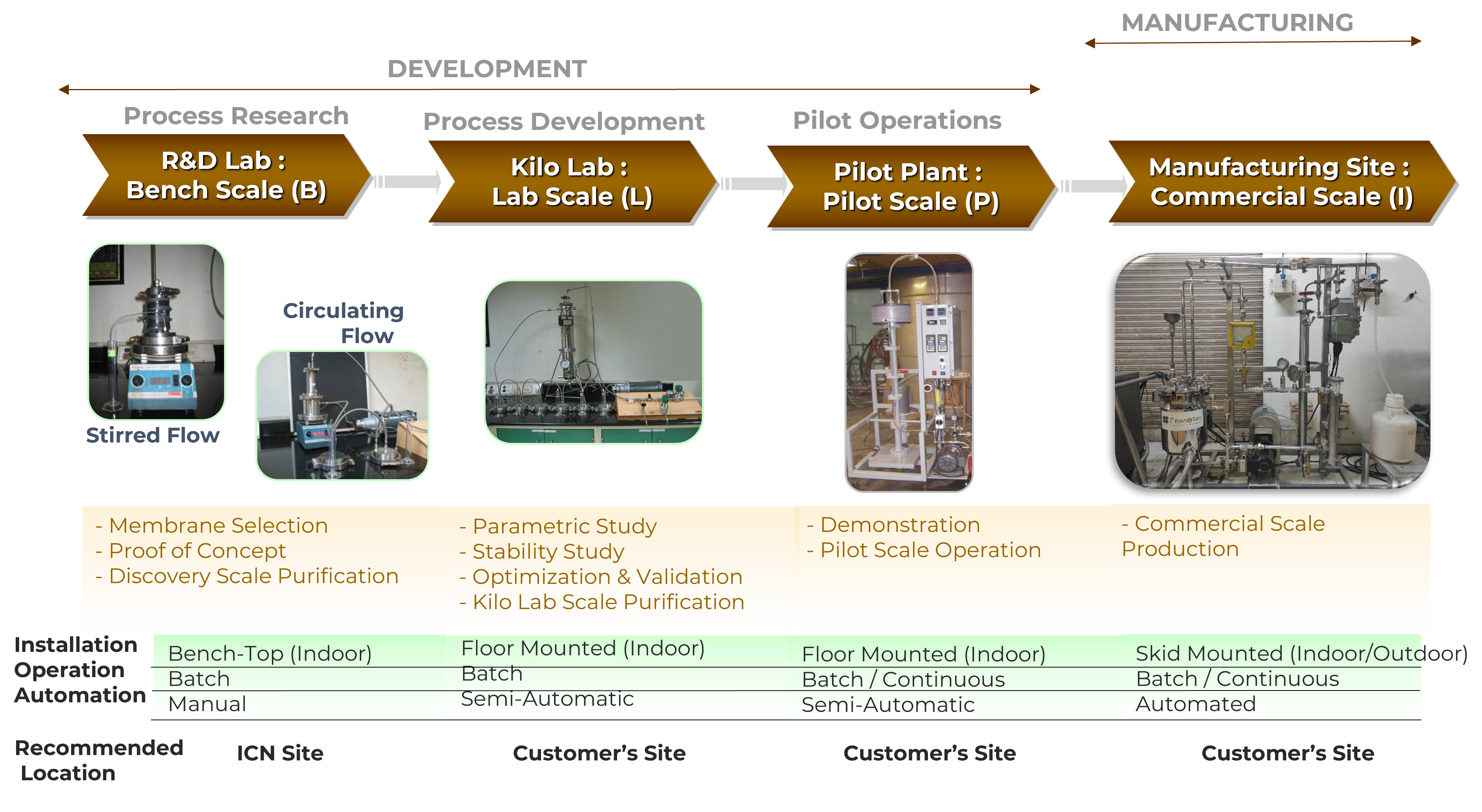

In addition to industrial systems, we have systems for R&D, Lab and Pilot scales for the complete process application development.

SolvDry Pervaporation & Vapor Permeation Application Development

SolvHyPe™ Hydraulic Permeation Application Development

PRE-ENGINEERED SYSTEMS

ICN offers a wide range of pre-engineered systems for standard applications in peptides, oligonucleotide, insulins & insulin biosimilars and small molecule APIs. Our standard offerings in these industries are:

SolvRefine™ – VOLOPURE™ (for volatile solvents) & NOVOPURE™ (for nonvolatile solvents) Systems – These are available in wide range of configurations – as standalone ZeoSep® PV/VP or PolyGSep VP and as hydrids with distillation.

SolvHype™ – CONCENTRATION & DIAFILTRATION Systems – These are available in a wide range of configurations. They mostly are Standalone Nanofiltration Systems and in some cases as hybrids with flash evaporation and stripping.

Pre-Engineered Systems for the following applications are available:

MAREX™

Small Molecule APIs

Peptide Synthesis

Oligonucleotide Synthesis

Insulins Synthesis

SYSTEM HIGHLIGHTS

- Standard models are available for R&D (only for SolvHyPe™), Lab, Pilot & Commercial Scales. Custom systems are also available.

- Common Utilities Required:

- Hot Oil / Steam (Only for large scale systems)

- Power

- Cooling Water

- Chilled Water

- Nitrogen

- Instrument Air

For SolvHyPe™ systems, Hot Oil/ Steam and Cooling water are generally not required.

COMMERCIAL MODELS

The systems are offered in two commercial models: –

- Outright Sales (Recommended for Custom Engineered & Large Capacity Plants)

- Leased

ICN offers modular systems on Lease in select geographies only. Major features & benefits of Leased systems

- No Investment required

- No requirement of internal Project team

- Rapid execution

- Containerized for easy logistics

- Modularized for easy Installation

- Option for Integrated Utility systems

- Only power and process water required from Lessee

- Option for Castors

- For easy movement of modular system from one plant / unit / block to other