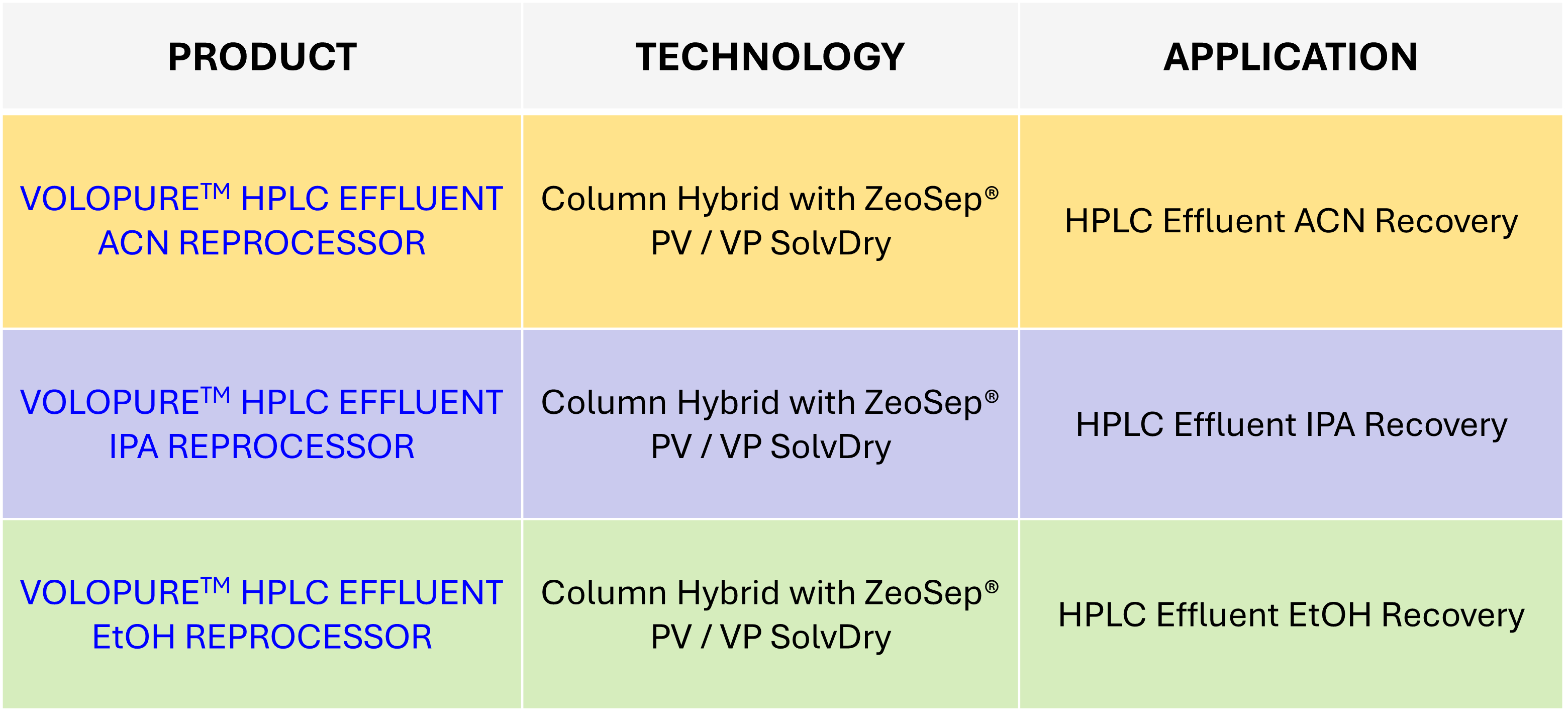

PRODUCTS

PEPTIDE SYNTHESIS

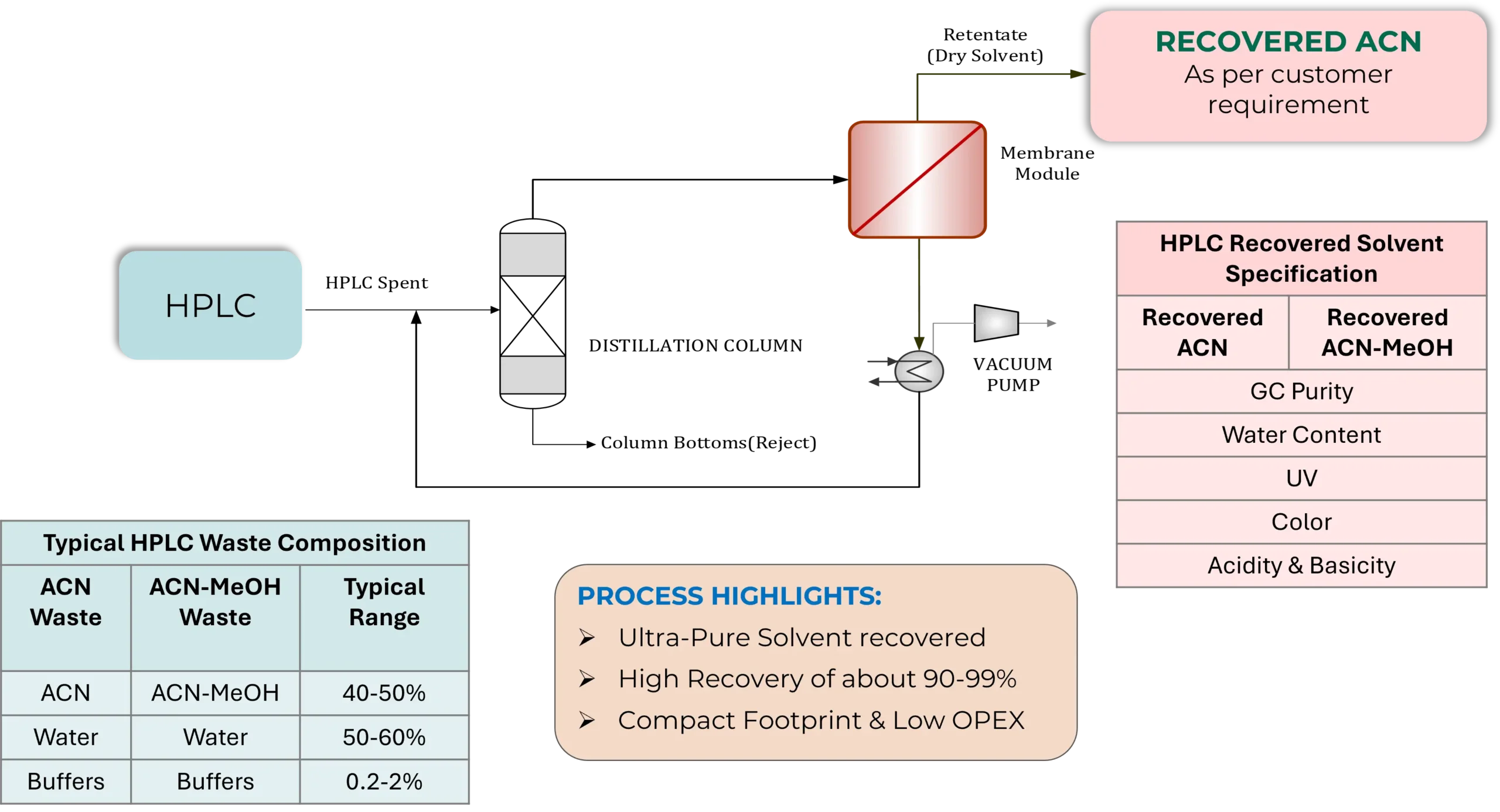

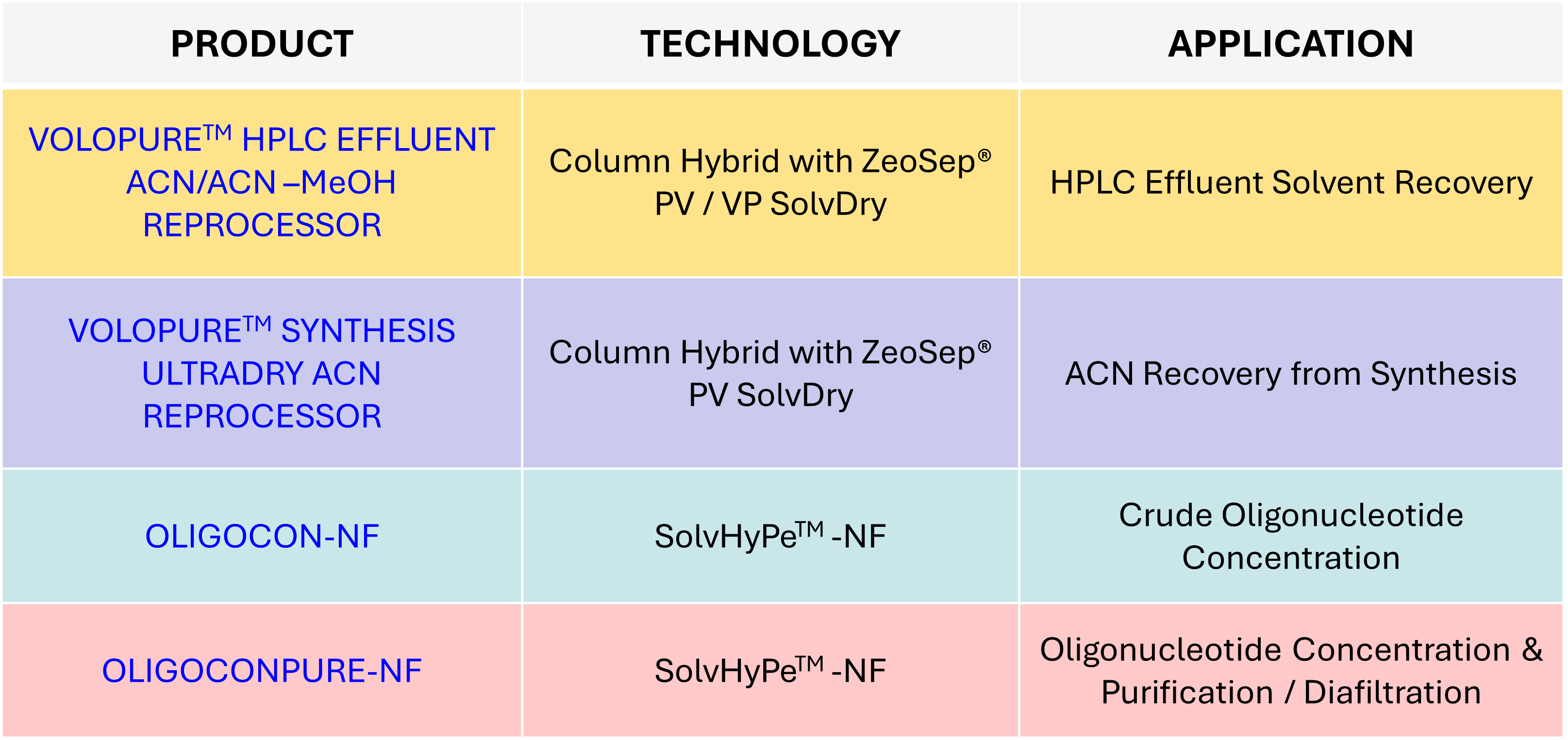

VOLOPURE™ HPLC Effluent ACN Reprocessor

The ZeoSep® and PolyGSep technology based VOLOPURE™ HPLC Effluent ACN Reprocessor can be used for Acetonitrile recovery from the effluent generated from HPLC during the purification stage. The system recovers the mobile phase solvent and returns it at a level of purity that can be reused in the peptide manufacturing process.

This drastically reduces solvent consumption and waste generation while maintaining high product purity.

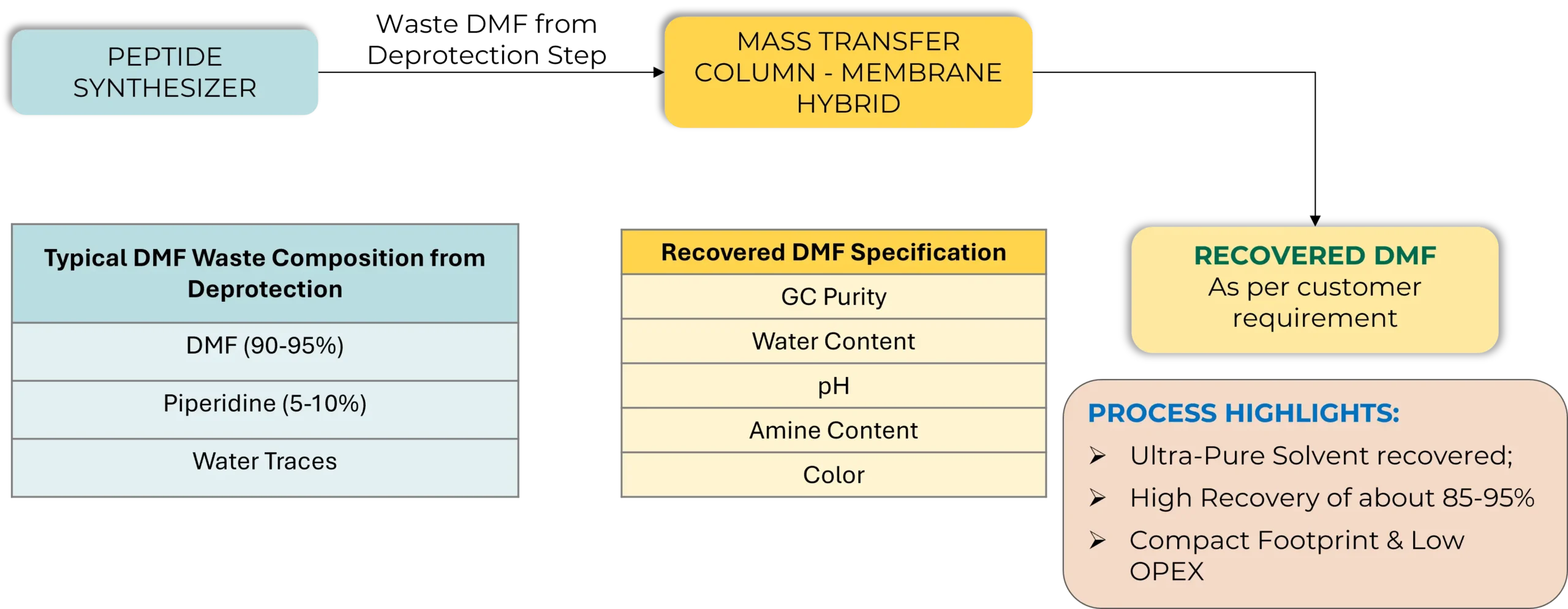

NOVOPURE™ Deprotection DMF Reprocessor

The system recovers Dimethylformamide (DMF) waste generated from deprotection step during the peptide synthesis and returns the DMF at a level of purity that can be reused in the manufacturing process.

It’s a Column-Membrane Hybrid system which has High recovery and Low OPEX with compact footprint. Typical waste composition has been shown in the table below.

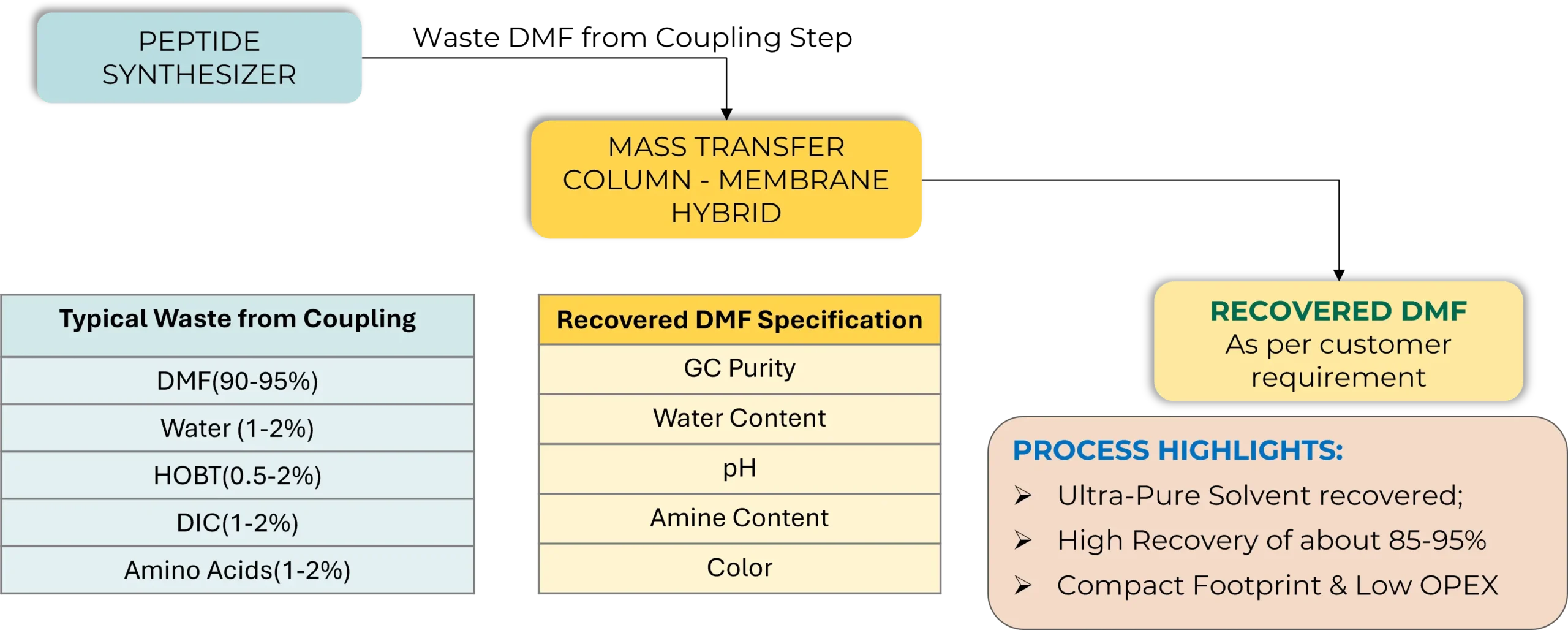

NOVOPURE™ Coupling DMF Reprocessor

The system recovers Dimethylformamide (DMF) waste generated from Coupling step during the peptide synthesis and returns the DMF at a level of purity that can be reused in the manufacturing process.

It’s a Column-Membrane Hybrid system which has High recovery and Low OPEX with compact footprint. Typical waste composition has been shown in the table below.

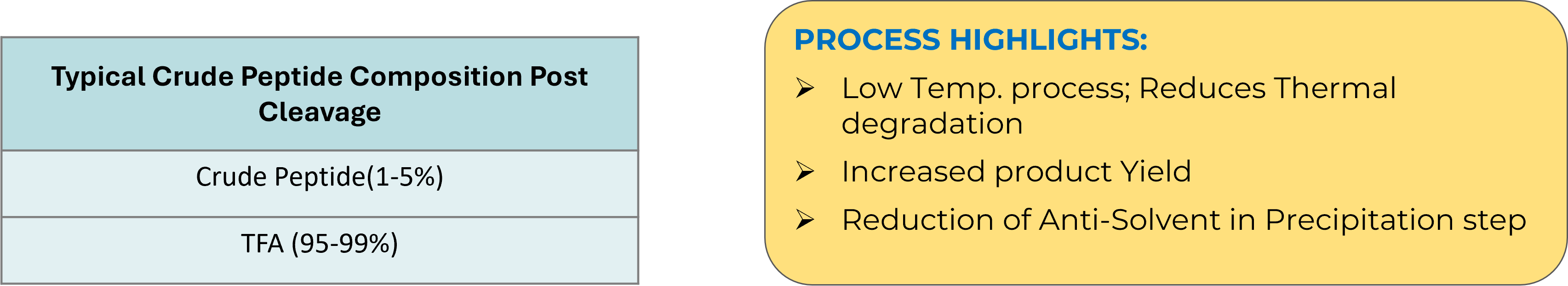

PepCon™ NF for Crude Peptide Concentration

The system concentrates Crude Peptide in Trifluoroacetic Acid (TFA) using solvent stable nanofiltration membranes. It operates at low temperatures and eliminates the risk of Peptide degradation during concentration.

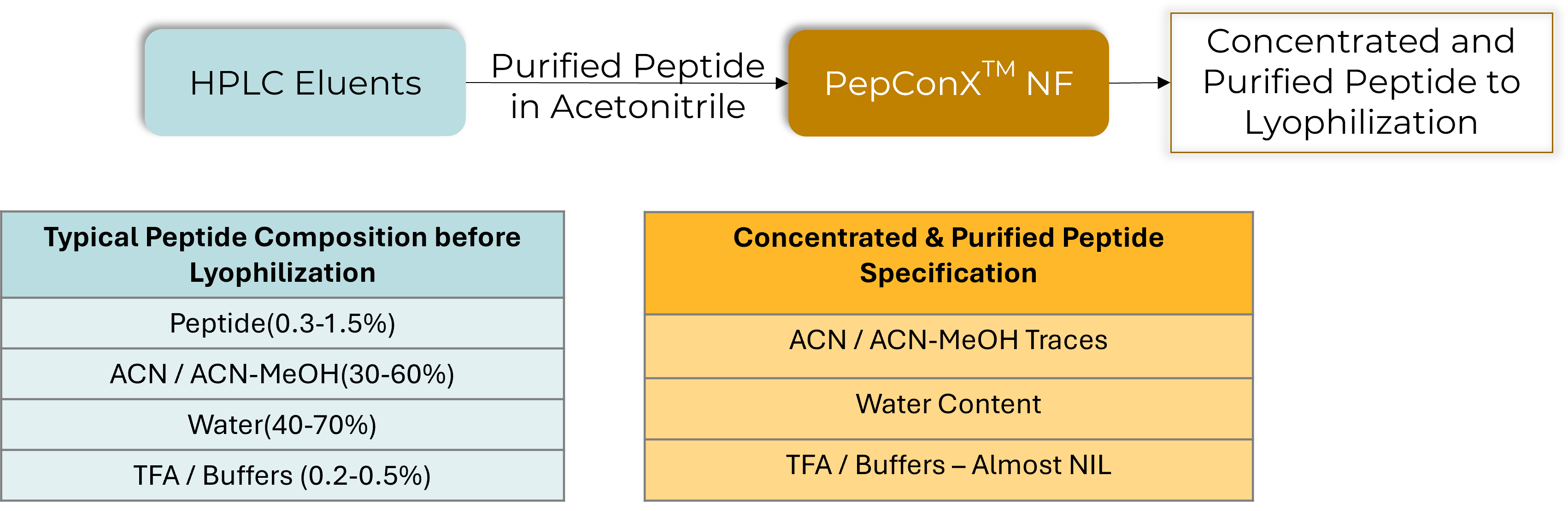

PepConX™ NF for Peptide Concentration & Purification

The system concentrates Peptide and removes residual solvents by Diafiltration. Residual Solvent concentration in the final product is reduced to the limit acceptable as per ICH guidelines. It operates at low temperatures and eliminates the risk of Peptide degradation during concentration. Our technology reduces the CAPEX and OPEX requirements for Lyophilizer.

OLIGONUCLEOTIDE SYNTHESIS

Just like peptides, there’s a growing interest in Therapeutic oligonucleotides in Pharmaceuticals. In making the solid phase production process more sustainable, there are challenges imposed by use of large volumes of hazardous reagents and solvents during synthesis and purification.

ICN offers sustainable solutions using Green Chemistry & Green Engineering principles that aid in waste reduction and energy conservation.

INSULINS SYNTHESIS

During the Insulins synthesis, different solvents are used during the purification. ICN provides solutions for the recovery of different solvents like Acetonitrile, Isopropanol and Ethanol.